|

|

|

Back to - Articles & Reports

A new 'Twist' on Mechanical Mixing

By Irv Cooper:

I always wanted a V-Tail glider, they look great in the air. But I was put off by the need to install mixing either electronically or the typical mechanical mixers. I did not want to tie up my only computer radio in a glider (plus I have found electronic mixing to be somewhat limited), adding an after market electronic mixer takes extra space in a crowed fuselage, sliding tray mixers add weight, and extra mechanical linkages introduce slop/play.

What I wanted the was low weight mixing of a computer radio and the flexibility of a mechanical mixer but without the slop.

It took several weeks of thinking about it, but I believe I have come up with a new 'Twist' on mechanical mixing giving me all the benefits I was looking for. So I bought a Hobby Lobby Cumulus '97 glider and gave my idea a try.

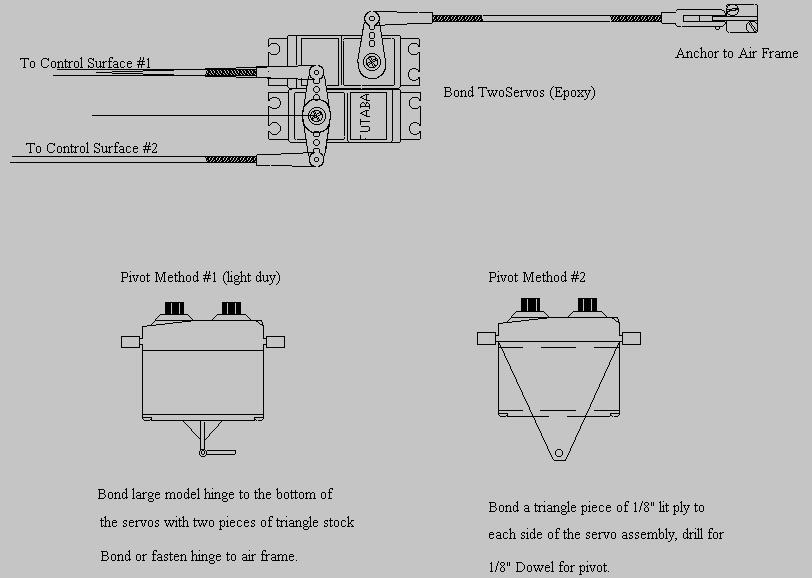

The first illustration shows the basic concept. It is simple, I bond (Epoxy) two servos together and then built a pivot on the bottom either with a large scale model hinge or by bonding two lite ply sides on my servo assembly and add a 1/8" pin (Dowel) at the bottom. (See Illustration).

The servo for elevator control has the control arm going to a fixed point on the fuselage. And the servo for the ailerons (rudders) has a arm going to each control surface. Elevator input rocks the servo assembly back and forth (duplicates the sliding tray motion). In spite of what my drawing shows, I find 'Z' bends work best at the servo arms to allow for both the servo turning and rocking motions. I recommend the lite ply pivot method for applications where there would be higher loads on the control surfaces.

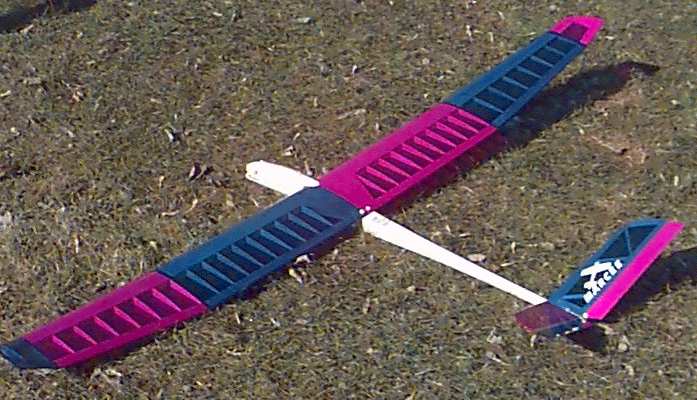

Illustration #2 shows the assembly installed in my Cumulus '97. I used two FMA S90 servos and the model hinge method in the Cumulus. The application is light weight and the hinge and epoxy has held up fine including some pretty rough landing treatment. The same lack of space that makes it hard to see the mixer setup in the Cummulus '97 also makes normal mechanical mixing even more difficult.

If you have any question Email Irv Cooper ijcooper@juno.com